Our standard steam coils deliver consistent and reliable heating performance. These coils offer exceptional heat transfer, ensuring efficient system operation in even the most demanding conditions.

Let us be your source for standard steam coils. Contact a representative today!

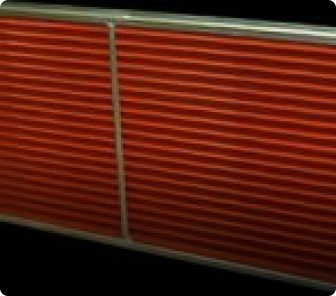

Round seamless copper tubes are mechanically expanded into the fin collars of the secondary surface. The mechanical expansion provides a permanent metal-to-metal bond for efficient heat transfer. Tubes are staggered in the direction of airflow and only return bends are used – NO reduced tube wall in the bend radius by using hairpin bends.

We have over 20 different surfaces available. Please contact us if construction other than what is above is needed.

Corrugated plate type fin that is die-formed. Fin collars are full-drawn to provide accurate control of fin spacing and maximum contact with tubes.

Aluminum fin thickness of .008 inch standard with optional (.010). Optional copper fin thicknesses available are (.006) (.008) and (.010). Fins per inch available 6 through 14.

Seamless copper with die-formed holes that provide a parallel surface to the coil tube for strong brazing joints.

Red brass Schedule 40 male pipe thread (MPT) is standard with optional copper female pipe thread (FPT) available. Maximum fin length of 120 inches with same end connections. Any fin height over 48 inches will have two supplies and two returns.

Using 16-gauge minimum thickness material, 1 1/2″ flanges are die-formed to permit easy stacking and mounting. Intermediate tube supports are supplied on coils over 44″ fin length with an additional support every 42″ multiple thereafter.

Full G-90 galvanized steel standard with optional stainless, aluminum and copper.

All coil assemblies are leak tested under water at 315 PSIG air. Standard construction is suitable for 25 PSIG steam pressure. Heavier wall, high pressure construction available up to 100 PSIG.

PERFORMANCE IS CERTIFIED under ARI Standard 410. All coil performance ratings are according to Commercial Coils, Inc.’s ARI certified selection software.